Slitting, die-cutting, and laminating of functional films.

Functional films for smartphones and automotive applications - Comprehensive support for various film processing.

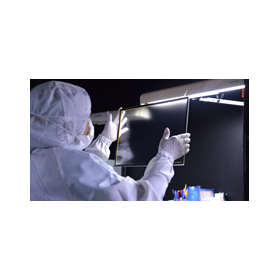

Parts used in smartphones, robots, automotive applications, and measuring instruments require various functions such as "insulation," "shielding," "shatter prevention," "reflection prevention," and "light diffusion." To achieve these, laminating optical materials like functional films and OCA with substrates such as resins and glass is effective. Meisei Electric can provide useful proposals for various laminating devices and complex shapes, including flat surfaces, curved surfaces, and uneven shapes, thanks to our clean room environment and years of accumulated processing technology and knowledge. We can support everything from prototype development to mass production, so please feel free to contact us. 【Variation】 - Functional film processing - Adhesive tape processing - Vacuum lamination processing - LCD-related components For more details, please contact us or download the catalog.

- Company:明星電気 本社(世田谷区用賀)、東北営業所(郡山市)、中部営業所(春日井市)、白河工場(西白河郡泉崎村)

- Price:Other

![Bonding processing of sound-absorbing materials and thermal insulation materials [Glass cloth × Glass wool]](https://image.mono.ipros.com/public/product/image/ac7/2000587972/IPROS73565383914099910574.jpeg?w=280&h=280)

![[Processing Technology] Area Calendar [Vegetation and Formwork Sheet]](https://image.mono.ipros.com/public/product/image/4ef/2000492792/IPROS62195313341191601500.png?w=280&h=280)